Other Projects

Presented here are selected projects from my past professional experience. The ultimate output for these projects was physical rather than digital, but there are many similarities to UX design worth highlighting: creating and designing against user scenarios, developing and working within design systems, collaborating with graphic designers and content creators, and closely working with stakeholders and end users.

SAS Experience

The SAS Experience, at SAS Institute, is a corporate museum that tells the story of the company’s past and present through printed graphics, video, art, interactive displays, physical artifacts and models, and augmented reality. I was involved with this project from inception to completion, working closely with a host of specialists and leading many parts of the project myself, to tell SAS’s story in a way that embodies its brand and showcases its values. My responsibilities ran the gamut from large-scale strategizing to minute detail work. I collaborated on the overall spatial scheme and layout, designed the millwork and graphics mounting systems, and designed and fabricated the campus model. I produced sketches, renderings, and drawings throughout the process, adjusting as necessary to feedback from corporate marketing and the company’s brand manager.

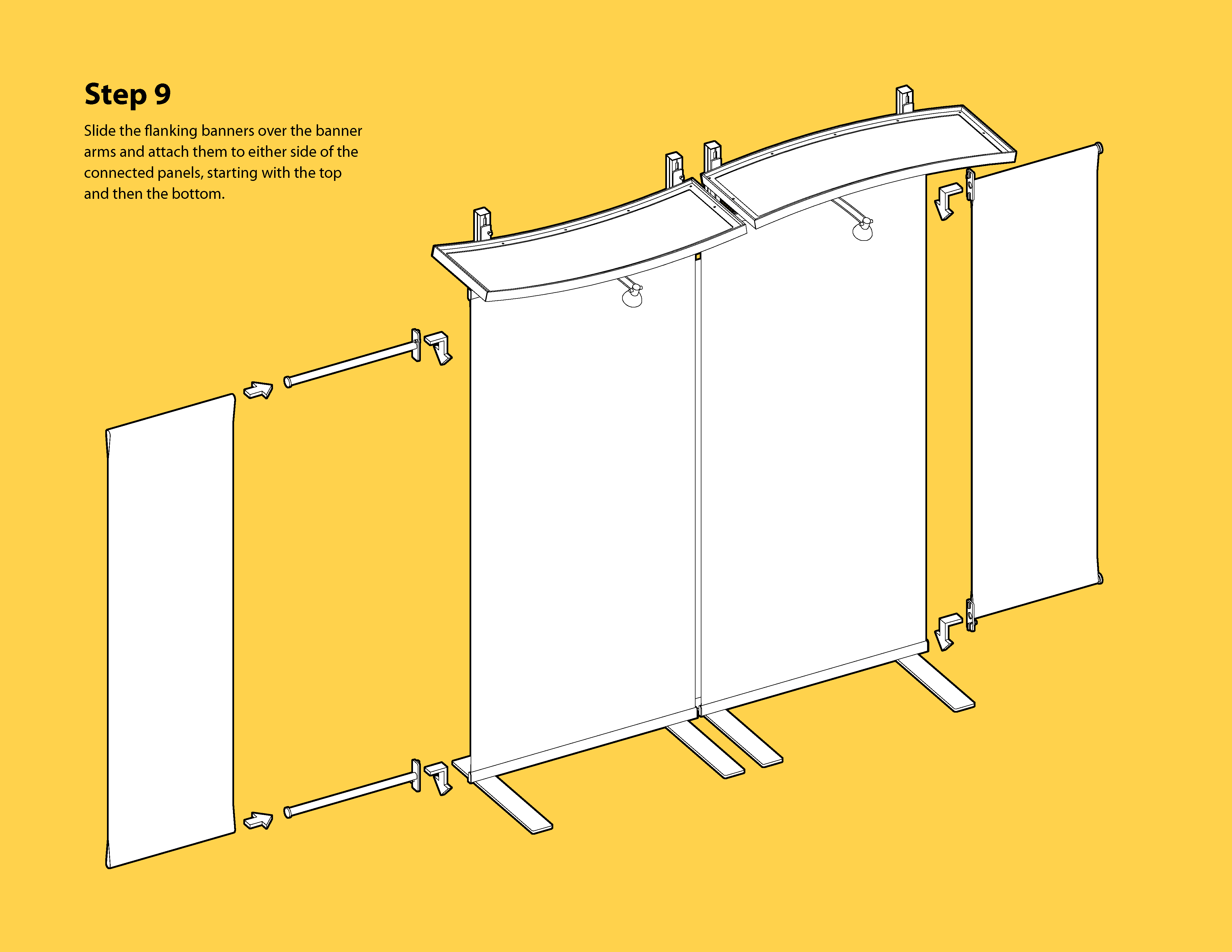

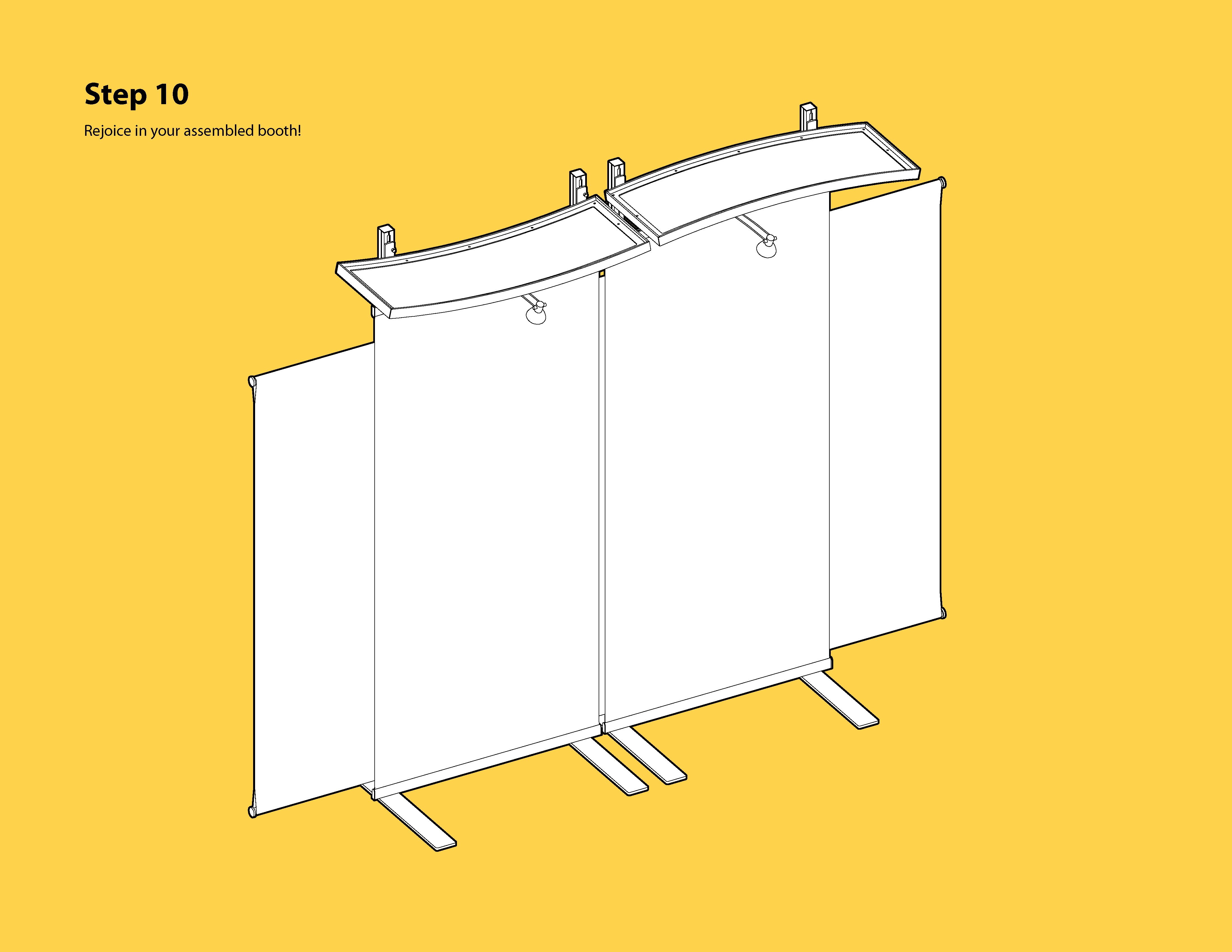

JCS Exhibit System

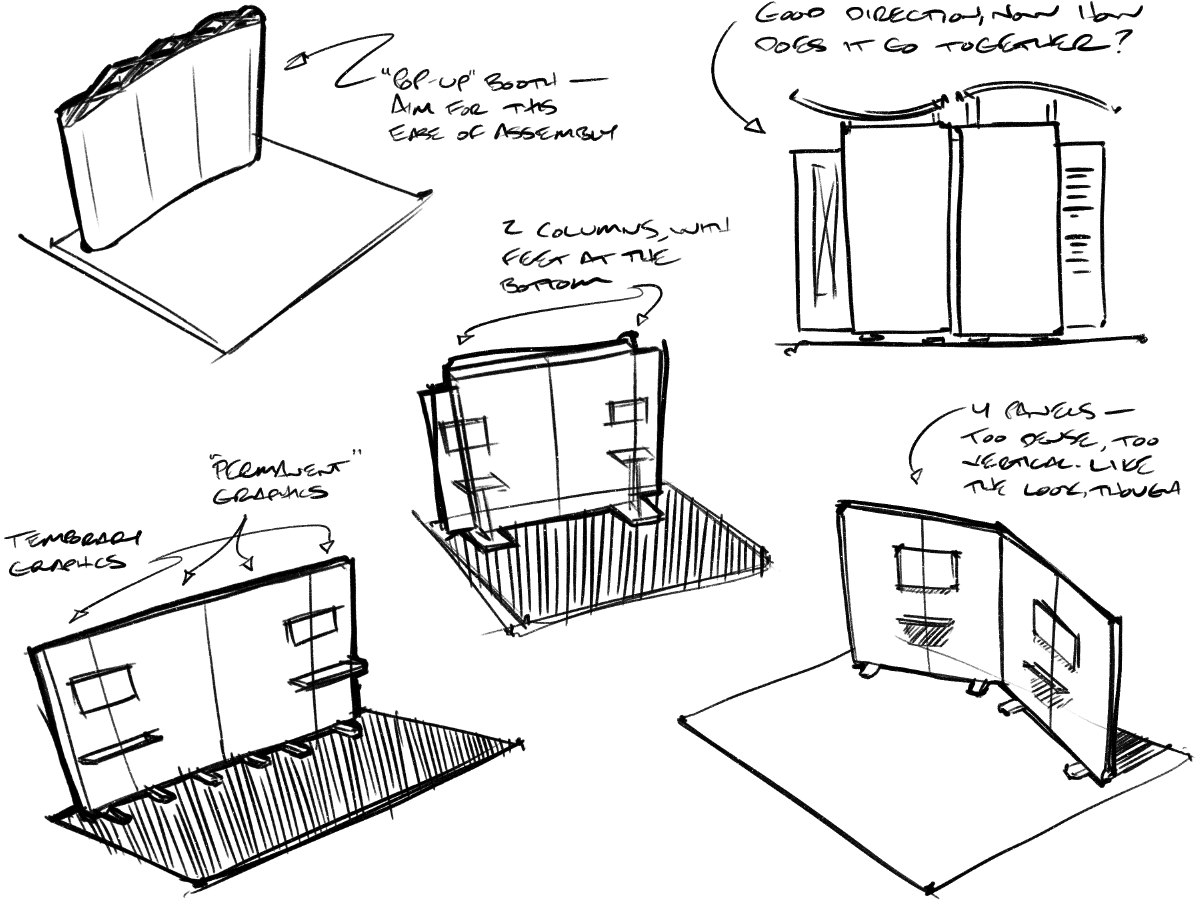

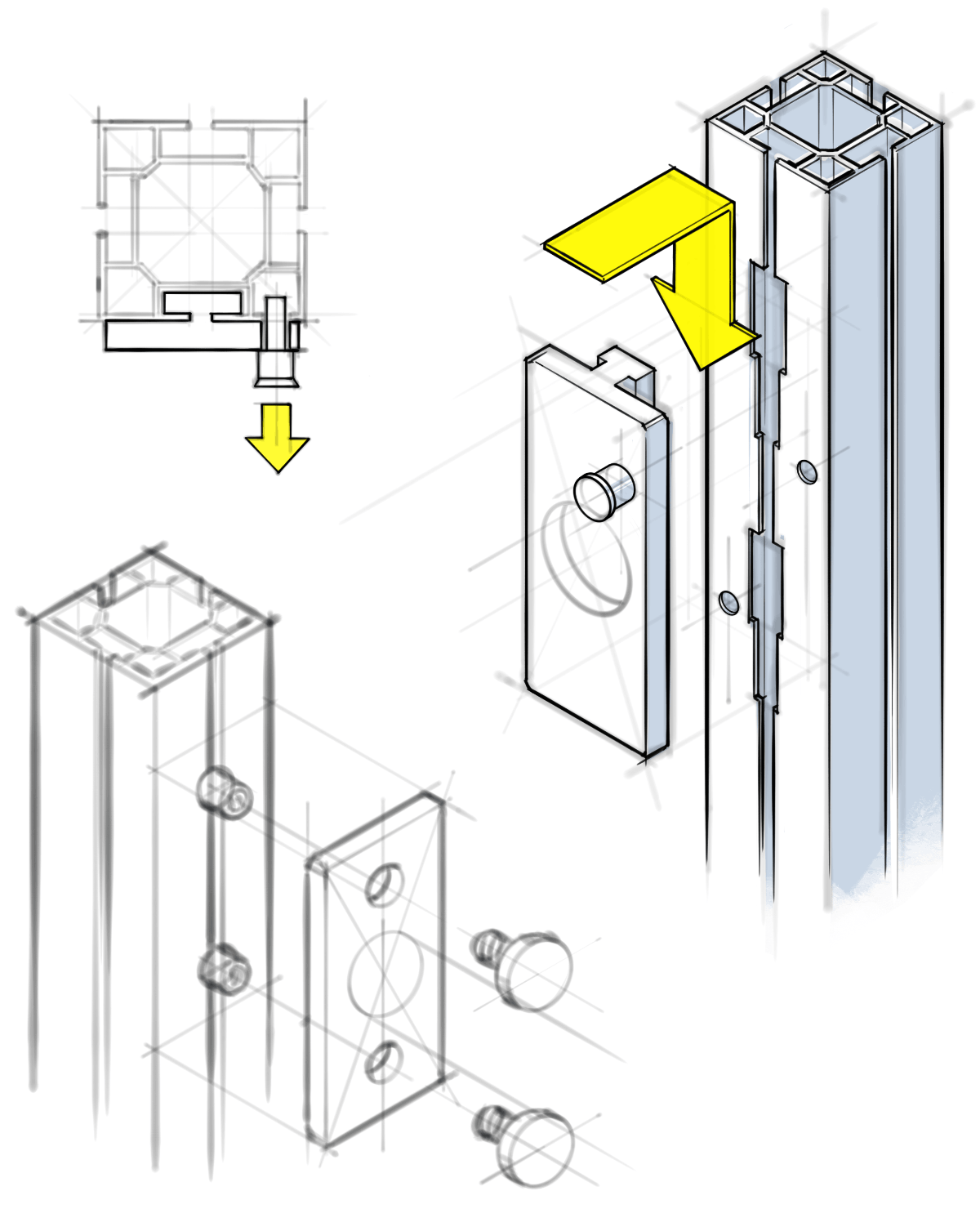

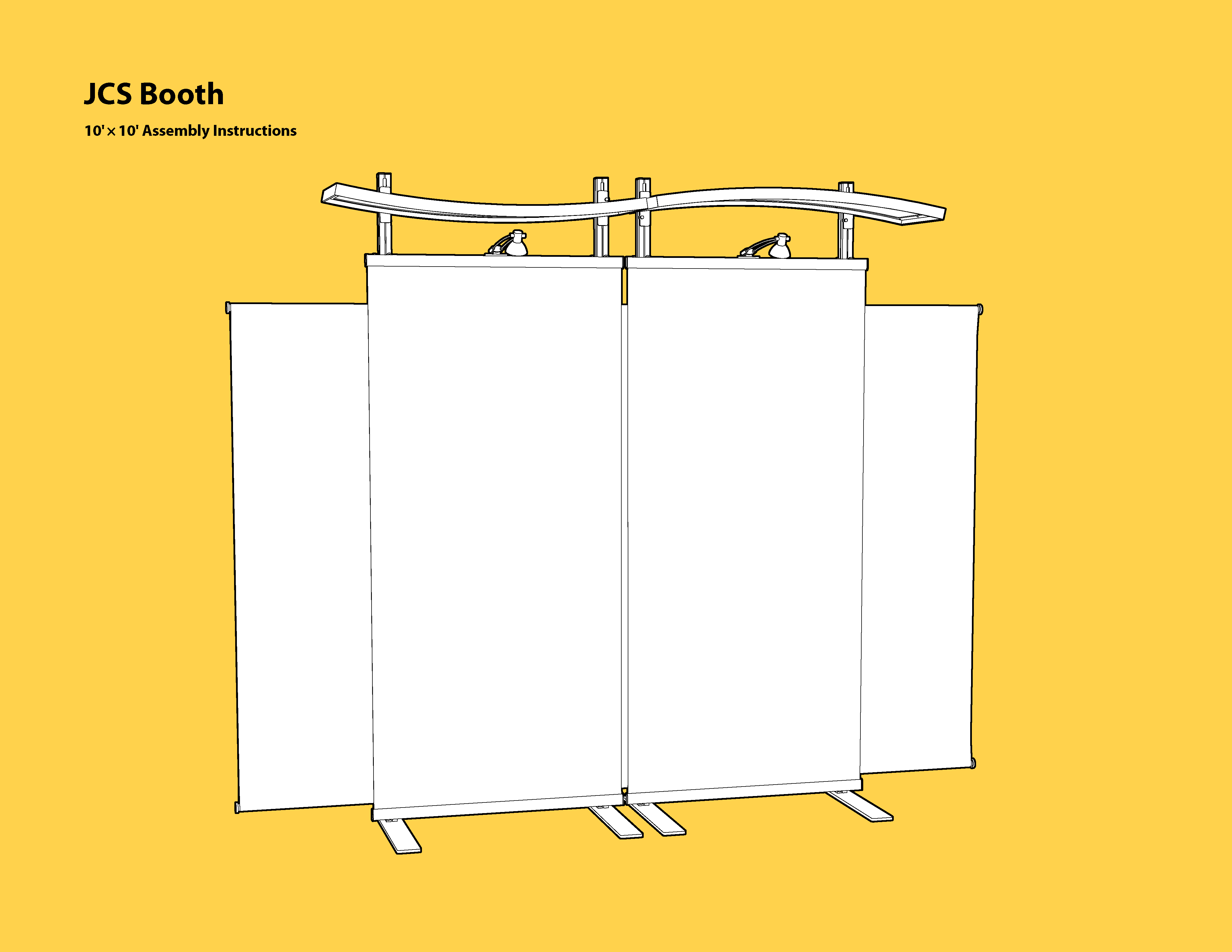

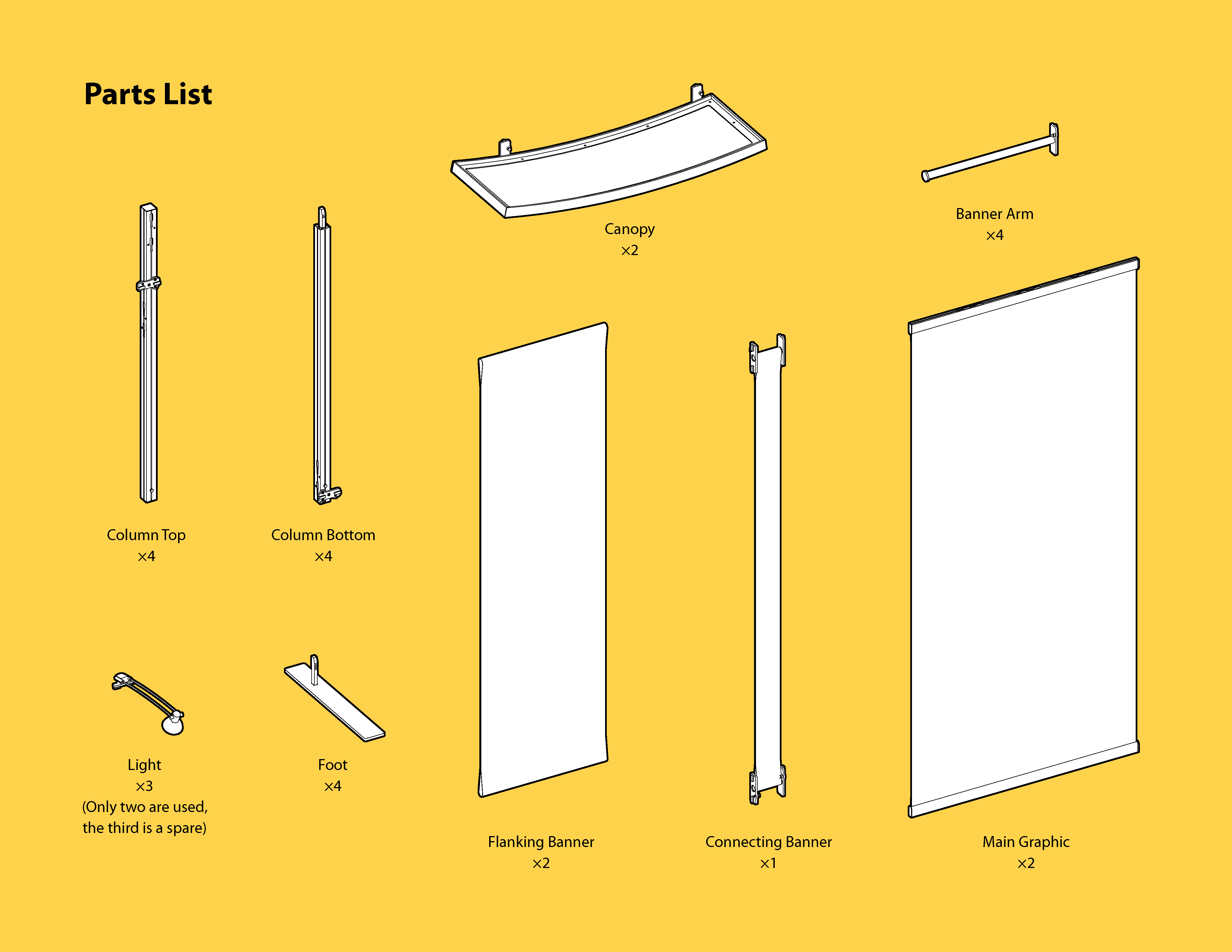

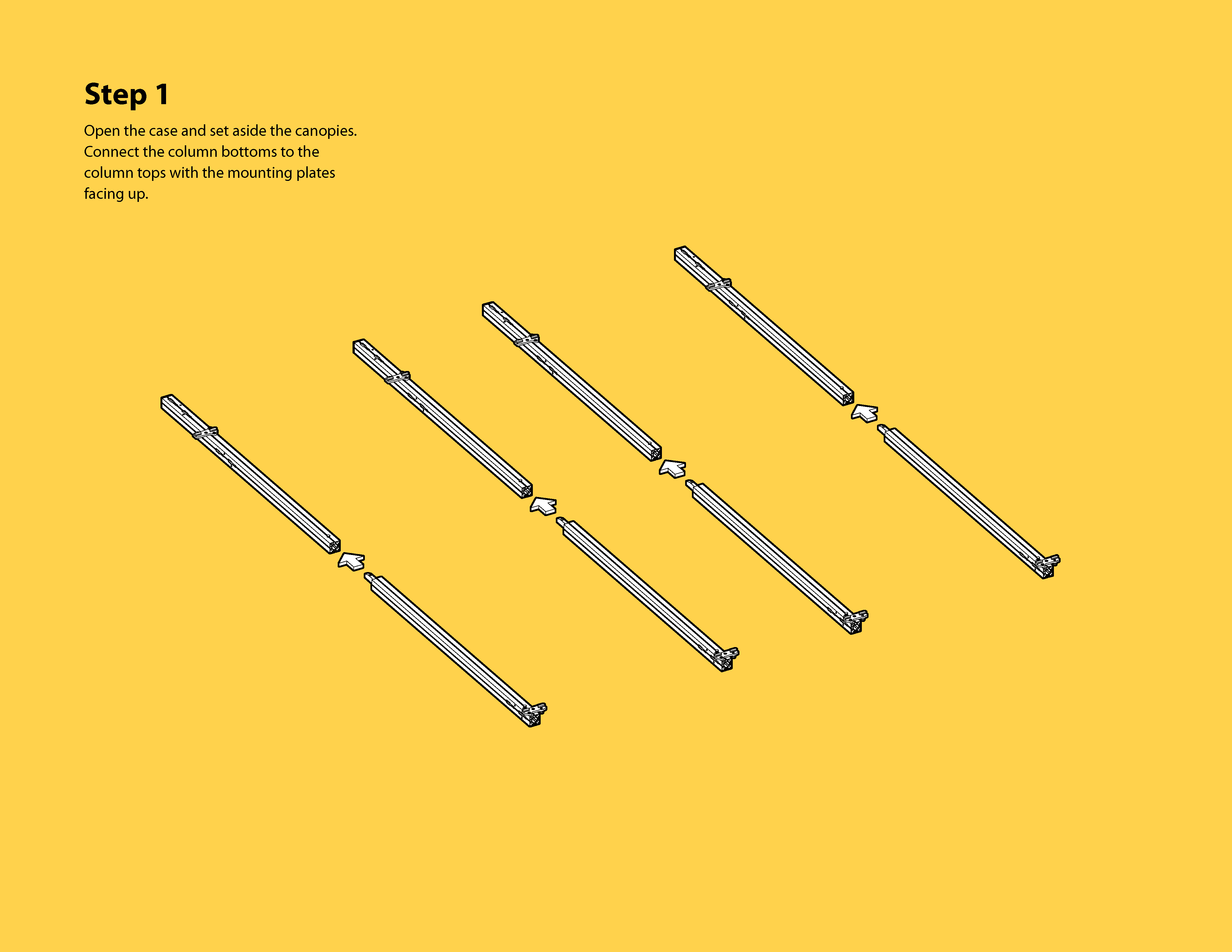

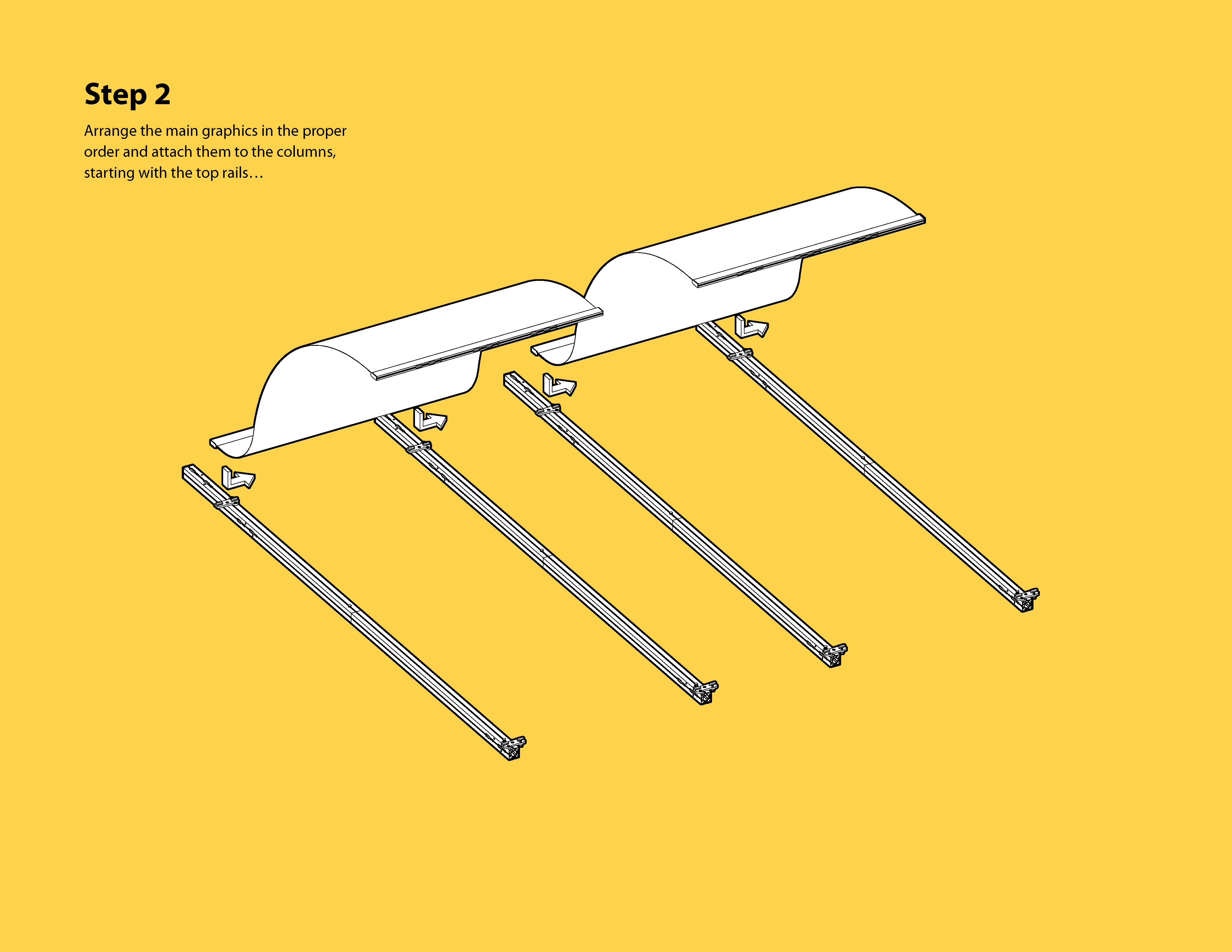

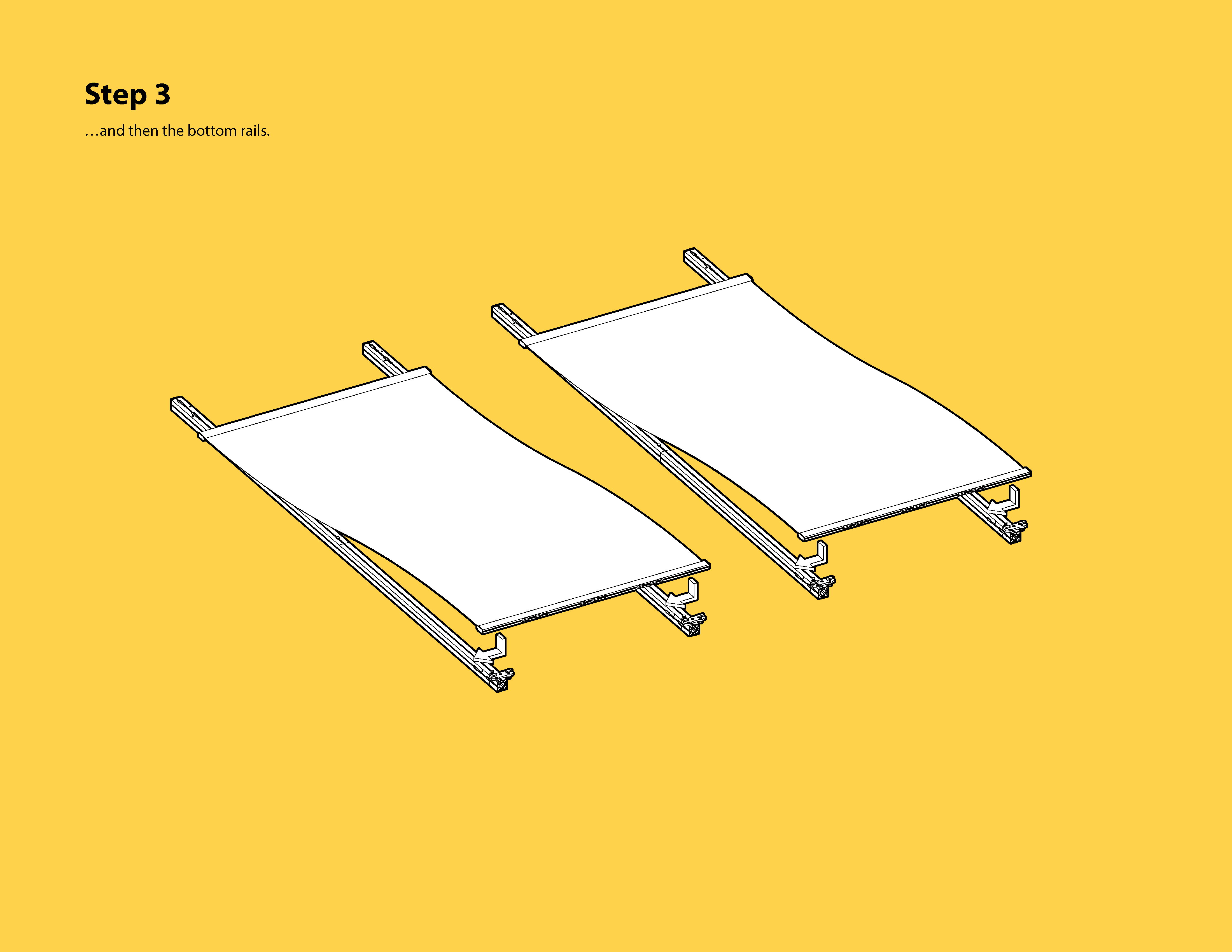

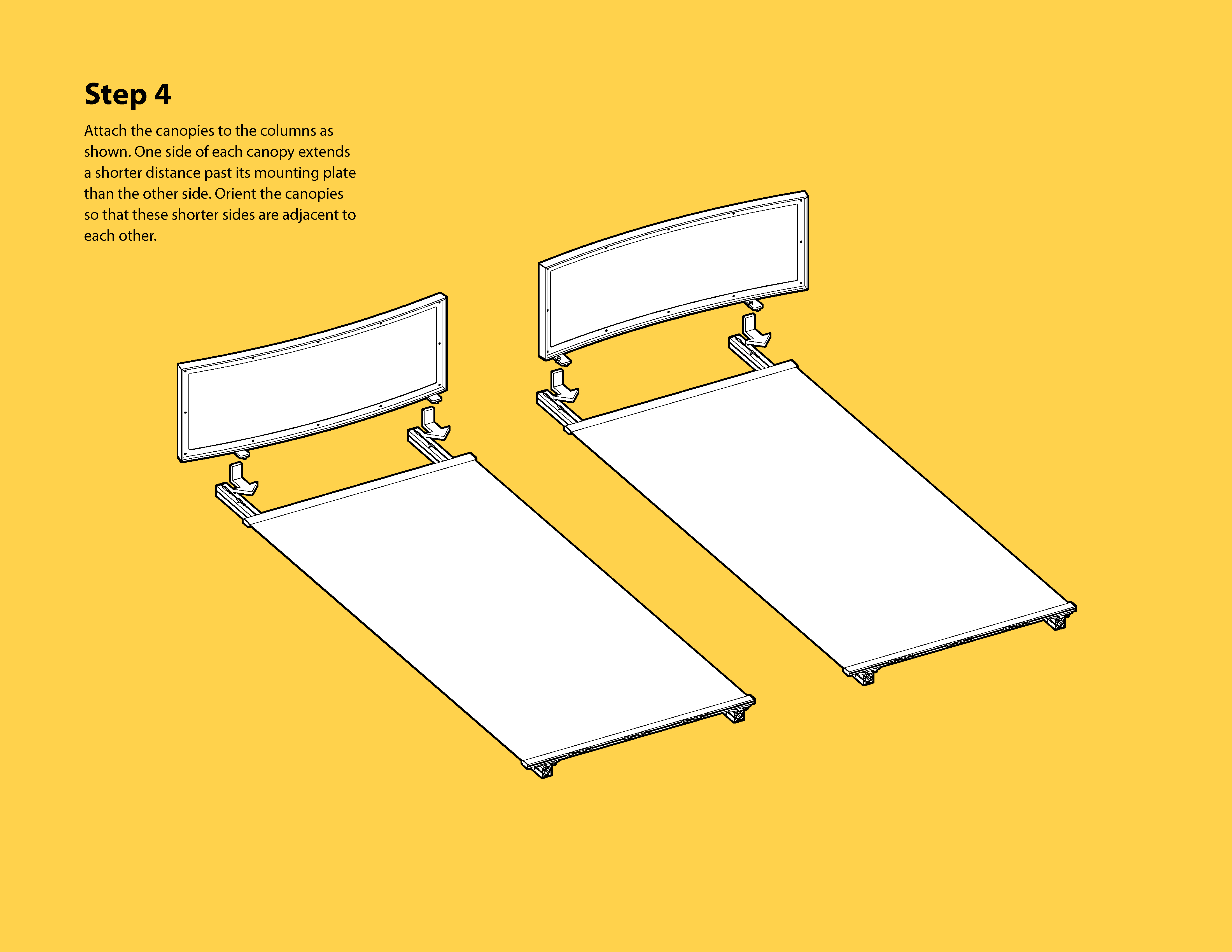

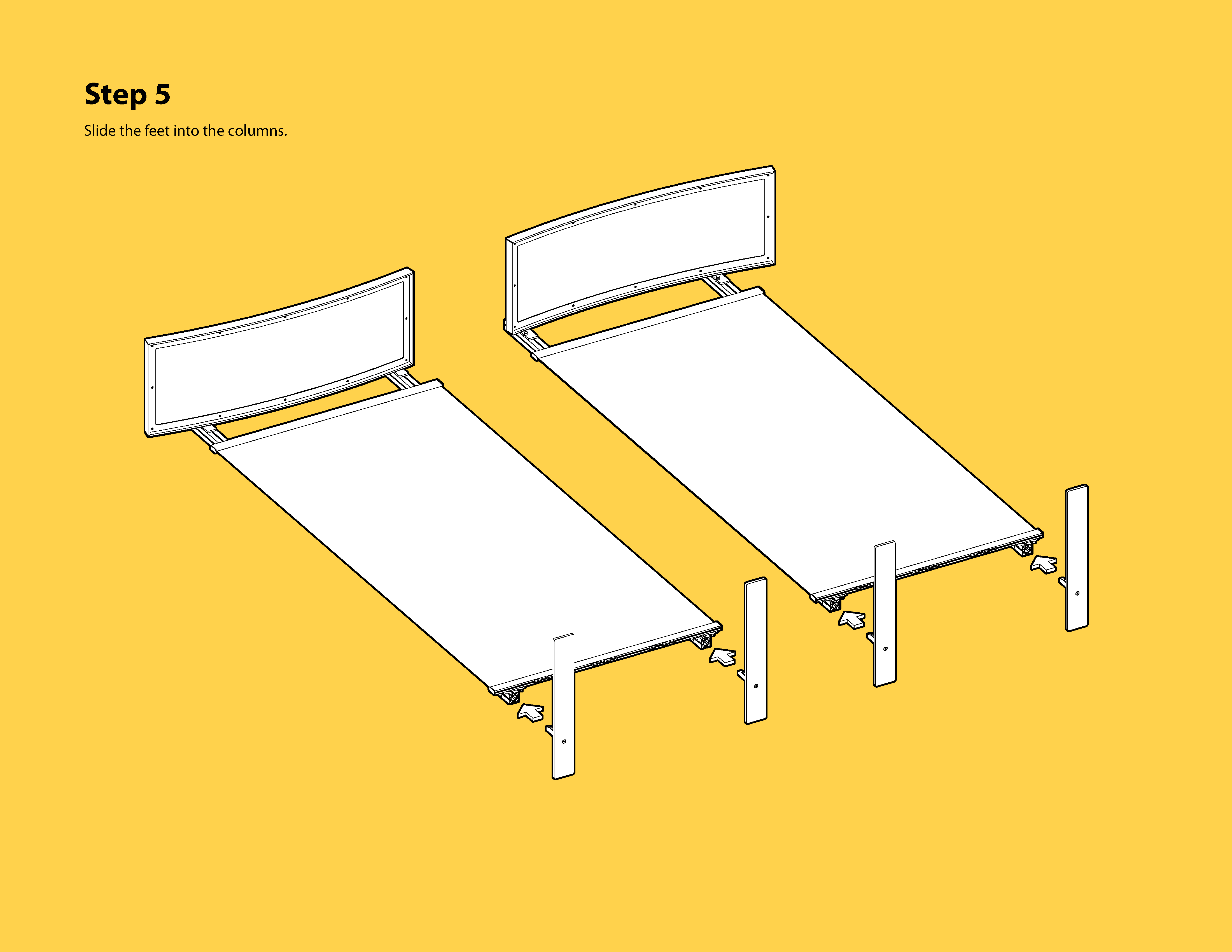

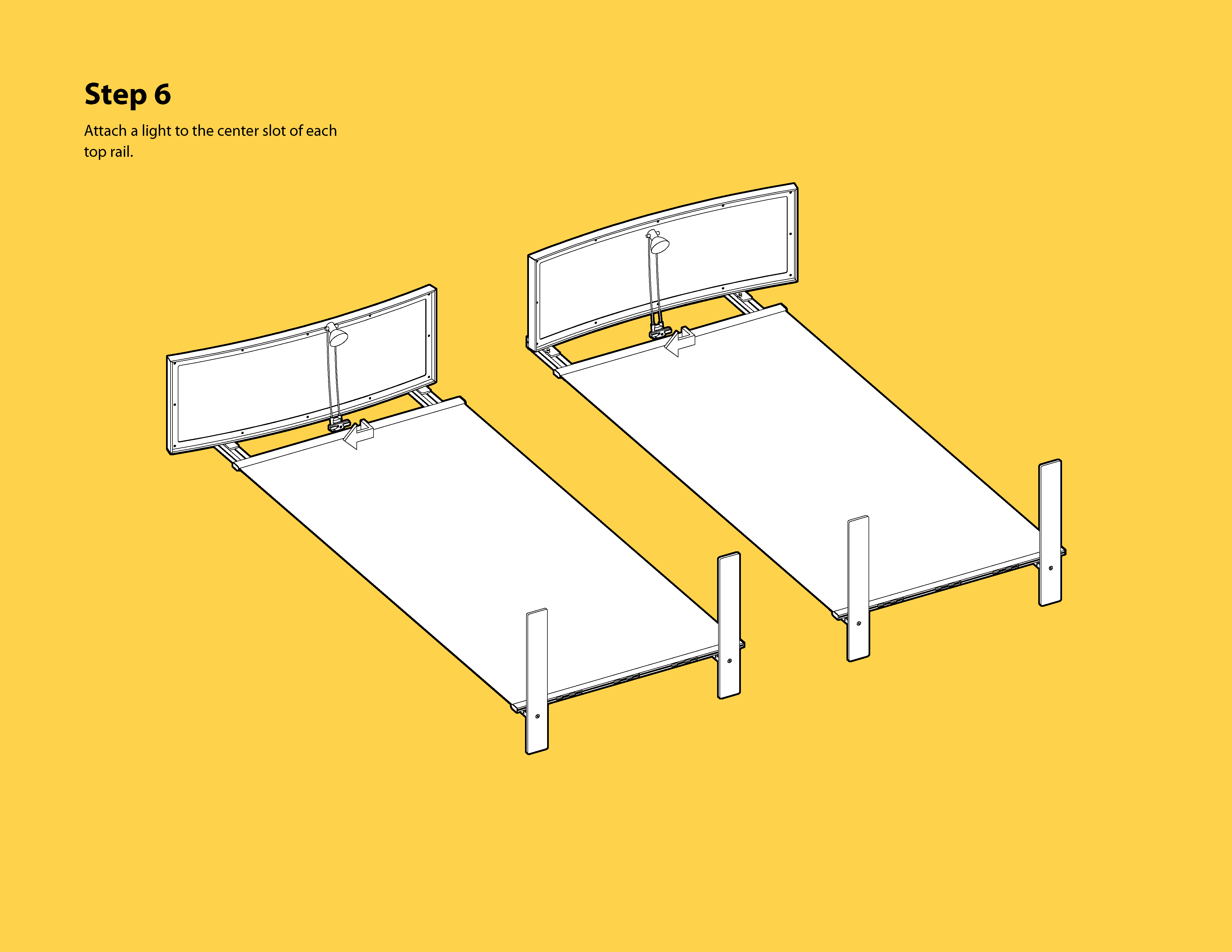

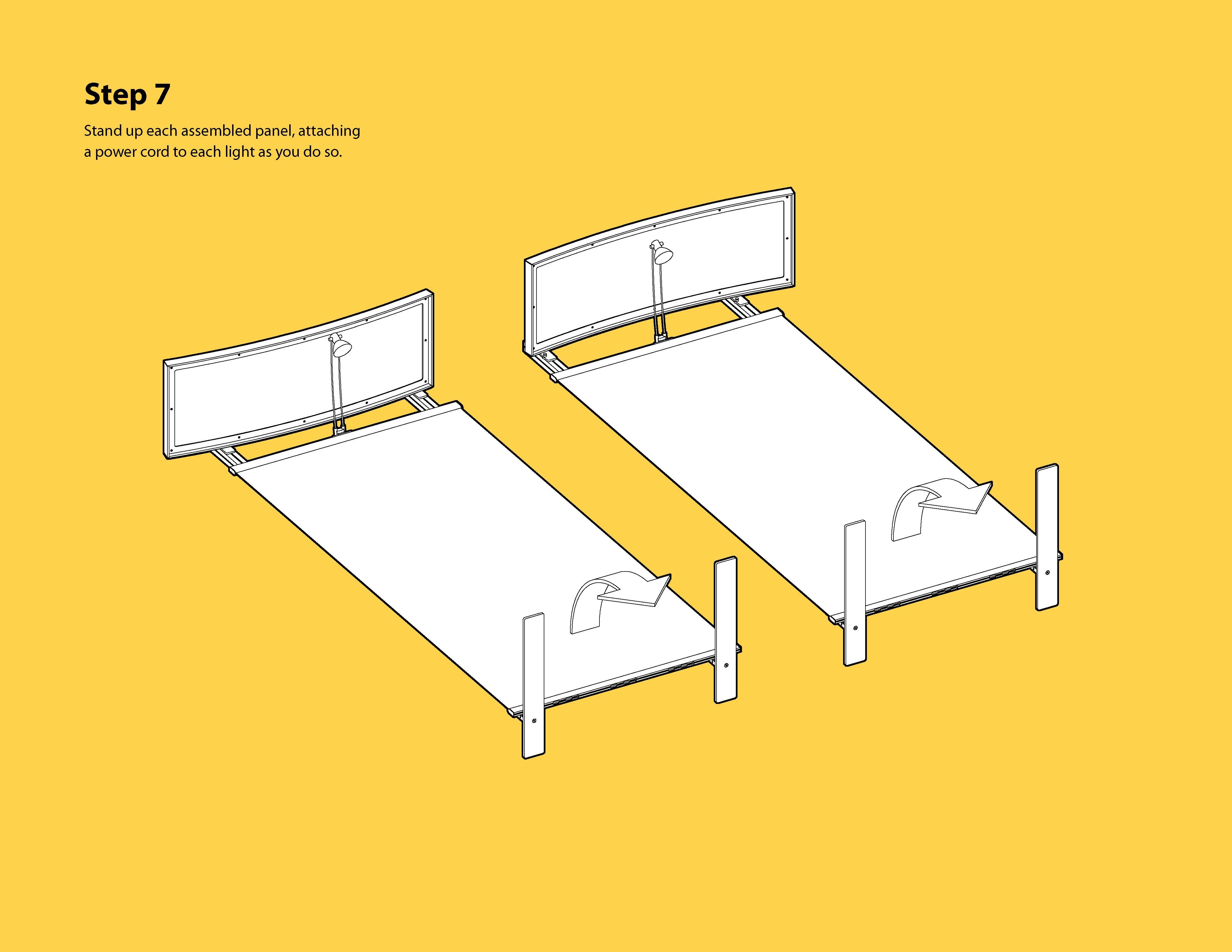

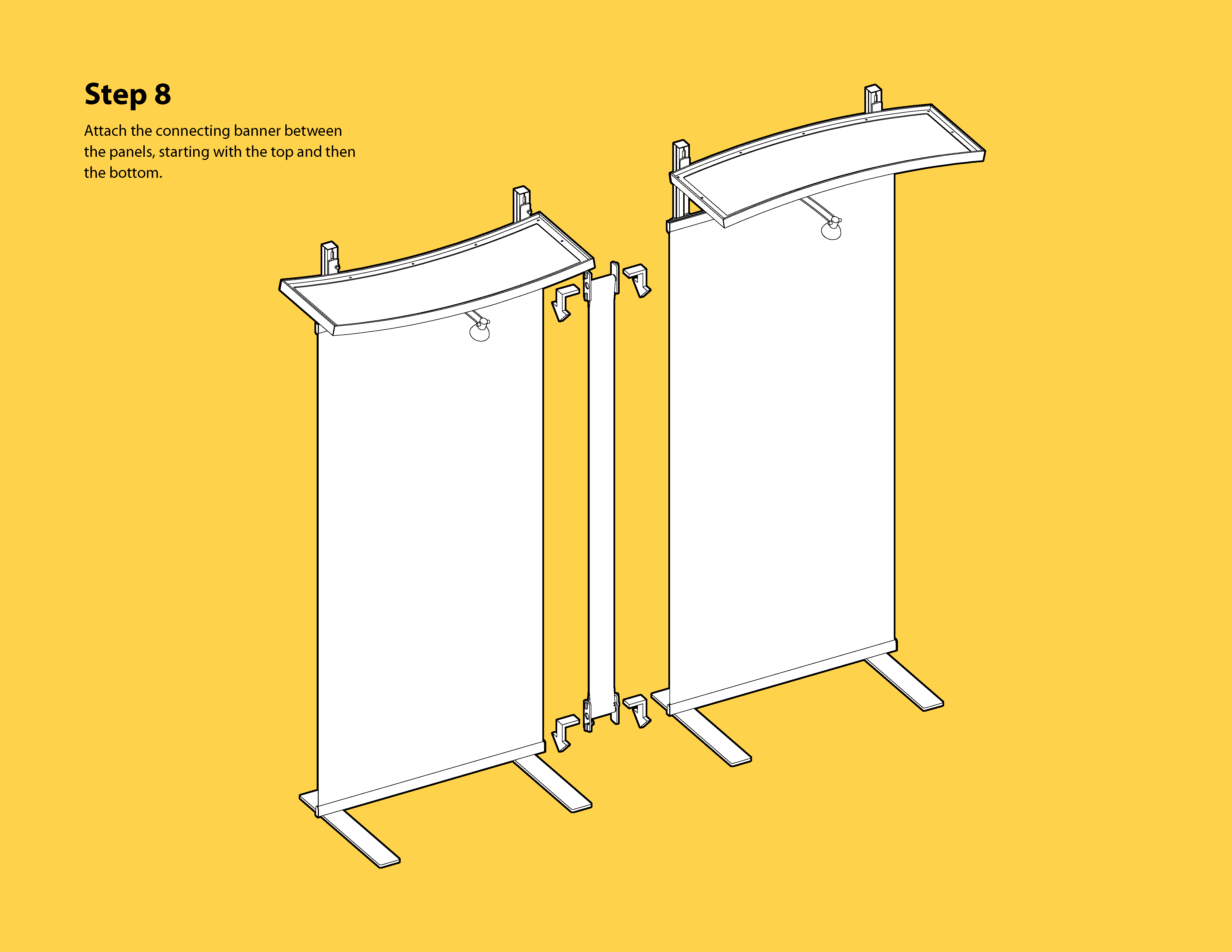

My brief for this project, designed at SAS Institute, was to develop a new exhibit system for 10' × 10' and 10' × 20' trade show booths for use by SAS sales and marketing reps. At the time, SAS owned two off-the-shelf systems: a “pop-up” style booth, which was easily assemblable, and a more complex system with high on-site labor expenses. Internal clients were asking for something that could split the difference. The JCS system sets SAS apart from the sea pop-up booths on a typical show floor while eliminating on-site labor costs. I led design and implementation, met with users and company stakeholders, sketched concepts, built detailed CAD models, fabricated prototypes, created graphic templates and training materials, and oversaw in-house production. Twenty JCS kits were produced and have been shipped and used across the United States hundreds of times.

Cricket Trailer

The Cricket, designed at TAXA Outdoors, is a travel trailer aimed at camping enthusiasts. Compact and lightweight, this design eschews many of the luxuries associated with high-end RVs in favor of essential amenities and a highly-configurable cargo space. When I began at TAXA, the Cricket concept had been stewing in the principal’s mind for some time, and existed mainly as rough sketches and a cardboard mockup. In my two years there, I worked closely with the principal to firm up the design, further research the target market, and develop details and components throughout the trailer. I produced concept sketches, CAD models, and technical drawings. I fabricated many prototype elements myself and worked with outside vendors for many others. When I left the project, the Cricket had progressed from that early cardboard mockup to two fully-functional prototypes, complete with fully designed and fabricated interiors. Production began shortly after and continues to this day.